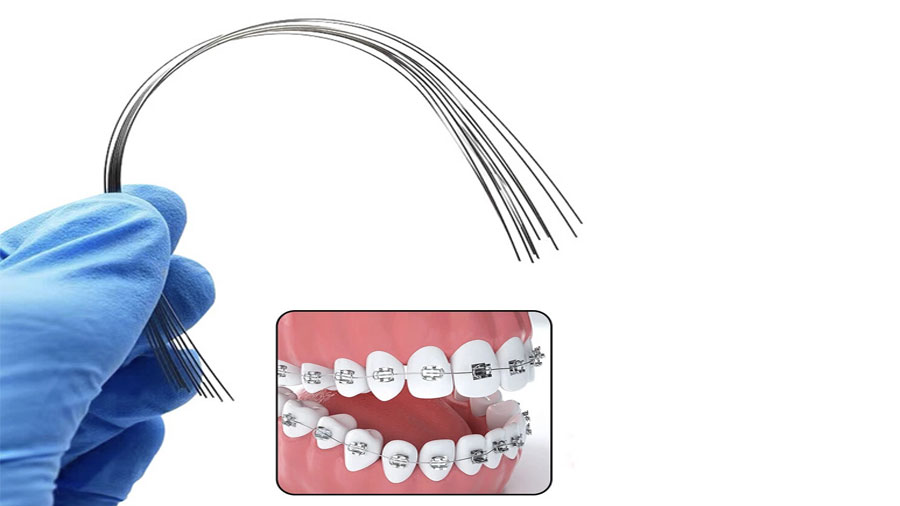

Copper-NiTi (CuNiTi) wires are an advanced type of orthodontic archwire that incorporates copper into the traditional nickel-titanium (NiTi) alloy. These wires are engineered to improve control over transformation temperatures and mechanical properties, making them a superior choice for orthodontic treatments. The addition of copper allows for precise customization of activation temperatures, enabling orthodontists to deliver consistent and predictable forces tailored to each patient’s needs.

Table of contents [Show]

- Composition and Material Properties

- Thermal Properties and Phase Transformation

- Clinical Advantages

- Storage and Handling Considerations

- Mechanical Properties and Clinical Behavior

- Effects of Clinical Use and Thermocycling

- Clinical Applications

- Comparative Performance

- Future Directions and Research

- Clinical Recommendations

- Conclusion

Composition and Material Properties

Chemical Composition

Copper-NiTi wires are composed of:

Nickel: 44-48.31%.

Titanium: 46.69-51%.

Copper: 3.83-4.65%.

Other elements: 0.2-0.3% (including chromium at 0.08-0.35%).

This carefully balanced composition ensures the wires maintain their unique thermal and mechanical properties, offering reliable performance in clinical settings.

Available Temperature Variants

Copper-NiTi wires are available in three main temperature variants, defined by their austenite finish (Af) temperatures:

27°C CuNiTi: Superelastic Copper NiTi, active below mouth temperature.

35°C CuNiTi: Thermoelastic Copper NiTi, active near mouth temperature.

40°C CuNiTi: Thermoelastic Copper NiTi, active above mouth temperature, requiring heat activation.

These variants allow orthodontists to select the most appropriate wire for each stage of treatment, optimizing both efficiency and patient comfort.

Thermal Properties and Phase Transformation

Transformation Temperatures

CuNiTi wires are designed with precise transition temperatures that dictate their behavior:

27°C variant: Superelastic properties are active at room temperature.

35°C variant: Balances flexibility and force delivery, activating near mouth temperature.

40°C variant: Requires thermal activation, providing higher force control for advanced stages of treatment.

Temperature-Dependent Behavior

The mechanical properties of CuNiTi wires change with temperature:

Below transformation temperature: The wire is in its martensitic phase, making it more flexible.

Above transformation temperature: The wire transitions to its austenitic phase, becoming stiffer and delivering optimal forces.

This temperature-dependent behavior allows orthodontists to customize treatment forces with precision.

Clinical Advantages

Predictable Force Delivery

CuNiTi wires provide consistent and reliable force delivery due to their engineered transformation temperatures. Advantages include:

Reduced variability between wire batches.

Precise control of force magnitude for different treatment stages.

Enhanced predictability in clinical outcomes.

The availability of three temperature variants enables orthodontists to:

Choose wires based on individual treatment needs.

Customize force levels for specific clinical situations.

Improve patient comfort while maintaining treatment efficiency.

Enhanced Clinical Performance

Research supports the superior performance of CuNiTi wires, including:

Greater resistance to permanent deformation compared to traditional NiTi wires.

Long-term maintenance of superelastic properties.

Improved clinical results through better force control.

Storage and Handling Considerations

Temperature Sensitivity

The properties of CuNiTi wires are highly sensitive to storage conditions:

Improper storage temperatures can alter mechanical behavior.

Fluctuations during shipping and handling may reduce wire performance.

Clinical Implications

To preserve optimal wire properties:

Follow manufacturer guidelines for storage and handling.

Minimize exposure to extreme temperature changes.

Educate clinical staff on proper storage practices.

Mechanical Properties and Clinical Behavior

Load-Deflection Characteristics

Studies show that CuNiTi wires exhibit:

Distinct load-deflection patterns for each temperature variant.

Consistent force plateaus, ensuring steady force application during treatment.

Better force retention over time compared to conventional NiTi wires.

Variability Among Manufacturers

Despite similar nominal specifications, CuNiTi wires can vary significantly between manufacturers:

Behavioral differences in 35°C wires have been observed.

Clinicians should verify product consistency to ensure predictable outcomes.

Effects of Clinical Use and Thermocycling

Thermocycling-Induced Changes

Prolonged clinical use and thermocycling can alter the mechanical properties of CuNiTi wires:

27°C CuNiTi: Composition changes to 47.86% titanium, 48.24% nickel, 3.83% copper, and 0.08% chromium.

40°C CuNiTi: Composition changes to 46.69% titanium, 48.31% nickel, 4.65% copper, and 0.35% chromium.

Long-Term Performance

Despite changes in surface characteristics, CuNiTi wires maintain their superelastic properties and force delivery capabilities after repeated loading cycles, making them a durable choice for extended treatments.

Clinical Applications

Treatment Planning Considerations

When selecting CuNiTi wires, orthodontists should consider:

27°C wires: Suitable for initial alignment due to lower force delivery.

35°C wires: Ideal for moderate corrections and standard alignment procedures.

40°C wires: Best for final detailing and precise tooth positioning.

Archwire Sequencing

A typical treatment sequence involves:

Starting with lower temperature variants for initial alignment.

Progressing to higher temperature variants as treatment advances.

Adjusting wire selection based on patient-specific factors such as pain tolerance and tooth mobility.

Comparative Performance

CuNiTi vs. Traditional NiTi

Copper-NiTi wires offer several advantages over conventional NiTi wires:

More precise and consistent transformation temperatures.

Greater resistance to permanent deformation.

Improved clinical predictability and performance.

Higher manufacturing consistency within temperature variants.

Future Directions and Research

Ongoing research focuses on:

Optimizing copper content for specific clinical applications.

Developing new temperature variants for specialized treatments.

Enhancing long-term stability of mechanical properties.

Improving consistency across different brands and wire batches.

Clinical Recommendations

To maximize the benefits of CuNiTi wires:

Verify manufacturer specifications and consistency before use.

Store wires according to recommended temperature guidelines.

Tailor wire selection to individual patient needs and treatment phases.

Monitor wire performance throughout treatment, as properties may change with use.

Conclusion

Copper-NiTi wires represent a significant advancement in orthodontic materials, offering enhanced control, predictable force delivery, and improved clinical outcomes. By understanding their unique properties, orthodontists can leverage these wires to optimize treatment efficiency and patient satisfaction. For dental labs and practices aiming to deliver high-quality orthodontic solutions, incorporating CuNiTi wires into treatment protocols is a step toward ensuring superior results and patient care.

At XDENT LAB, we are committed to supporting dental practices with cutting-edge materials and solutions like Copper-NiTi wires. As a trusted partner in Lab-to-Lab services, we ensure that every product meets the highest standards of quality and precision, empowering dental professionals to achieve exceptional results.

XDENT LAB is an expert in Lab-to-Lab Full Service from Vietnam, with the signature services of Removable & Implant, meeting U.S. market standards – approved by FDA & ISO. Founded in 2017, XDENT LAB has grown from local root to global reach, scaling with 2 factories and over 100 employees.. Our state-of-the-art technology, certified technicians, and commitment to compliance make us the trusted choice for dental practices looking to ensure quality and consistency in their products.

Our commitments are:

100% FDA-Approved Materials.

Large-Scale Manufacturing, high volume, remake rate < 1%.

2~3 days in lab (*digital file).

Your cost savings 30%.

Uninterrupted Manufacturing 365 days a year.

Contact us today to establish a strategy to reduce operating costs.

--------❃--------

Vietnam Dental Laboratory - XDENT LAB

🏢 Factory 1: 95/6 Tran Van Kieu Street, Binh Phu Ward, Ho Chi Minh City, Vietnam

🏢 Factory 2: Kizuna 3 Industrial Park, Can Giuoc Commune, Tay Ninh Province, Vietnam

☎ Hotline: 0919 796 718 📰 Get detailed pricing