Heat-activated nickel-titanium (NiTi) wires are a revolutionary advancement in orthodontics, offering clinicians greater control over force application and improved patient comfort. These wires leverage unique shape memory and superelastic properties, allowing them to respond to temperature changes in the oral environment. First introduced for commercial use in the 1990s, heat-activated NiTi wires have since become a cornerstone of modern orthodontic treatment.

This article explores the science behind heat-activated NiTi wires, their clinical advantages, mechanical properties, and applications in orthodontic treatment protocols.

Table of contents [Show]

What Are Heat-Activated NiTi Wires?

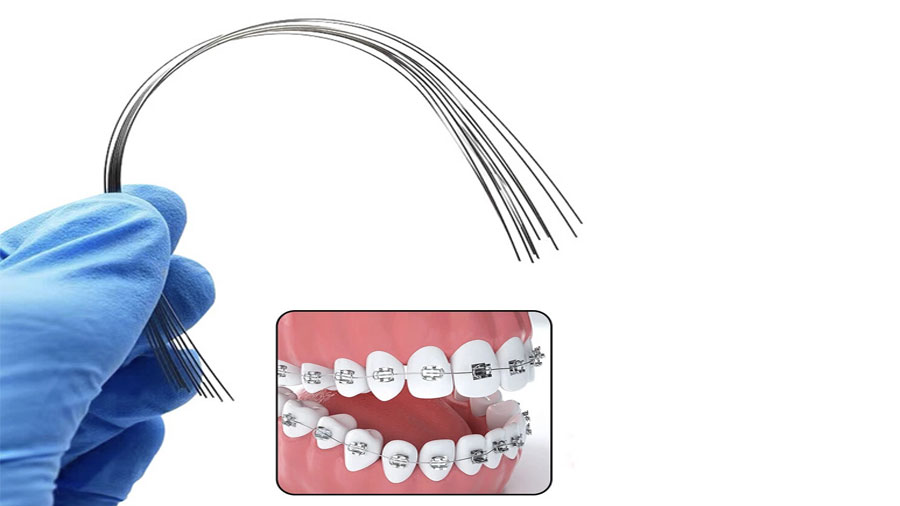

Heat-activated NiTi wires are orthodontic archwires made from nickel-titanium alloy, specifically engineered to deliver consistent and gentle forces during treatment. Their ability to change mechanical behavior in response to temperature fluctuations makes them superior to conventional wires.

Key Features:

Shape Memory: These wires "remember" their original shape and return to it when exposed to specific temperatures.

Superelasticity: They exhibit flexibility under stress and provide consistent force over a wide range of activation.

Temperature-Dependent Behavior: Their mechanical properties shift between flexible and rigid phases based on oral temperature, optimizing force delivery.

Shape Memory and Phase Transformation

The unique properties of heat-activated NiTi wires are rooted in their phase transformation characteristics, which occur due to changes in temperature.

Transition Temperature Range (TTR)

The TTR determines when the wire transitions between its two phases:

Martensite Phase (flexible): Occurs at lower temperatures, making the wire easier to engage in brackets.

Austenite Phase (rigid): Occurs at higher temperatures, where the wire stiffens and exerts optimal orthodontic forces.

Examples of TTR:

NeoSentalloy F200

Martensite finish (Mf): -51.60°C.

Austenite finish (Af): 29.37°C.

Heat-Activated NiTi

Mf: -64.13°C.

Af: 33.90°C.

These temperature ranges are critical for determining the wire's behavior during orthodontic treatment.

Temperature-Dependent Behavior

Below mouth temperature: The wire is in its martensitic phase, offering flexibility for easy placement.

At mouth temperature (37°C): The wire transitions to its austenitic phase, stiffening to deliver consistent orthodontic forces.

Testing at 55°C: Significant differences in mechanical parameters are observed between traditional and heat-activated NiTi wires, highlighting their temperature-responsive properties.

Clinical Advantages

Heat-activated NiTi wires offer several benefits that enhance the effectiveness and comfort of orthodontic treatment.

Optimal Force Delivery

These wires produce relatively low force magnitudes compared to superelastic NiTi wires of the same diameter.

Ideal for:

Initial alignment of severely crowded teeth.

Reducing patient discomfort during treatment.

Minimizing the risk of root resorption.

Constant Force Application

Heat-activated NiTi wires provide consistent force delivery over extended activation ranges.

They adapt better to tooth movement, reducing the need for frequent adjustments and improving treatment efficiency.

Clinical Effectiveness

Comparative studies show:

Similar effectiveness between heat-activated NiTi and conventional NiTi wires in reducing Little's Irregularity Index (LII).

Comparable pain levels and root resorption rates during the alignment phase.

Effective alignment using sequences with different activation temperatures (35°C and 37°C).

Mechanical Properties After Clinical Use

The performance of heat-activated NiTi wires after clinical use and sterilization has been extensively studied.

Load-Deflection Characteristics

Studies on 0.012" heat-activated NiTi wires reveal distinct load-deflection patterns.

Wires maintain their superelastic properties after clinical use, though some mechanical changes occur.

Larger diameter wires experience higher deformation stress when deflected by the same amount.

Durability and Sterilization Effects

Clinical use and sterilization procedures can impact the superelastic properties of NiTi wires.

Understanding these changes is crucial for determining optimal wire replacement intervals.

Material Composition Variations

Heat-activated NiTi wires come in different compositions, affecting their mechanical properties and clinical performance.

CuNiTi vs. NiTi

Copper-Nickel-Titanium (CuNiTi) wires represent a variation with distinct transformation temperatures and force delivery characteristics.

These differences allow clinicians to select wires tailored to specific treatment needs.

Clinical Applications and Treatment Protocols

Heat-activated NiTi wires are integral to modern orthodontic treatment protocols, particularly in archwire sequencing.

Archwire Sequencing

Orthodontists often use heat-activated NiTi wires in a graduated sequence:

Initial Alignment: Heat-activated NiTi wires at 35°C are used for initial tooth movement.

Progression: Transition to wires with 37°C activation temperature for advanced alignment.

This approach optimizes tooth movement while minimizing patient discomfort.

Temperature Considerations

Oral temperature fluctuates with food and beverage consumption.

Heat-activated wires temporarily become more flexible when exposed to cold items, reducing discomfort.

Return to body temperature restores optimal force levels, ensuring effective treatment.

Future Developments

Research continues to advance the capabilities of heat-activated NiTi wires:

Optimizing Transformation Temperatures: Tailoring TTR for specific clinical situations.

Enhanced Alloy Compositions: Developing new materials with improved mechanical properties.

Long-Term Performance Studies: Understanding durability and effectiveness over extended treatment periods.

Conclusion

Heat-activated NiTi wires represent a significant leap forward in orthodontic materials, combining shape memory, superelasticity, and temperature responsiveness to deliver optimal force application and improved patient comfort. Their ability to adapt to oral temperature changes makes them invaluable in modern orthodontic treatment protocols.

For dental practices seeking consistent quality and advanced orthodontic solutions, heat-activated NiTi wires are a reliable choice. At XDENT LAB, we specialize in providing state-of-the-art dental products and services, ensuring compliance with FDA and ISO standards to meet the needs of global dental practices.

Trust XDENT LAB for your dental outsourcing needs and experience the benefits of precision, consistency, and innovation.

XDENT LAB is an expert in Lab-to-Lab Full Service from Vietnam, with the signature services of Removable & Implant, meeting U.S. market standards – approved by FDA & ISO. Founded in 2017, XDENT LAB has grown from local root to global reach, scaling with 2 factories and over 100 employees.. Our state-of-the-art technology, certified technicians, and commitment to compliance make us the trusted choice for dental practices looking to ensure quality and consistency in their products.

Our commitments are:

100% FDA-Approved Materials.

Large-Scale Manufacturing, high volume, remake rate < 1%.

2~3 days in lab (*digital file).

Your cost savings 30%.

Uninterrupted Manufacturing 365 days a year.

Contact us today to establish a strategy to reduce operating costs.

--------❃--------

Vietnam Dental Laboratory - XDENT LAB

🏢 Factory 1: 95/6 Tran Van Kieu Street, Binh Phu Ward, Ho Chi Minh City, Vietnam

🏢 Factory 2: Kizuna 3 Industrial Park, Can Giuoc Commune, Tay Ninh Province, Vietnam

☎ Hotline: 0919 796 718 📰 Get detailed pricing